Construction composite train possible following regulation change

If a train’s car body is made of composite materials, the train’s weight will reduce by 20 to 30 percent. These weight savings will lead to lower energy consumption and a reduction of a least five percent of CO2 emissions, says Martijn Wolf, Technical Consultant at Ricardo Rail. Current European legislation does not allow train manufacturers to use composites for train car bodies. European project REFRESCO intends to adapt legislation to enable using this light, durable material in the construction of trains.

Martijn Wolf will give a presentation on the applications of composites in train construction on 19th November at the Rail Technology Conferences in Paris. Wolf is representing Ricardo Rail (formerly Lloyd’s Register Rail) in the REFRESCO project.

Composite

The railway sector currently only uses composites for non-bearing structural components. It is common to use steel for the car body of a train. “Composites are used for tables and partitions in trains. The nose of the high-speed Thalys train is also made of composite material, “says Wolf.

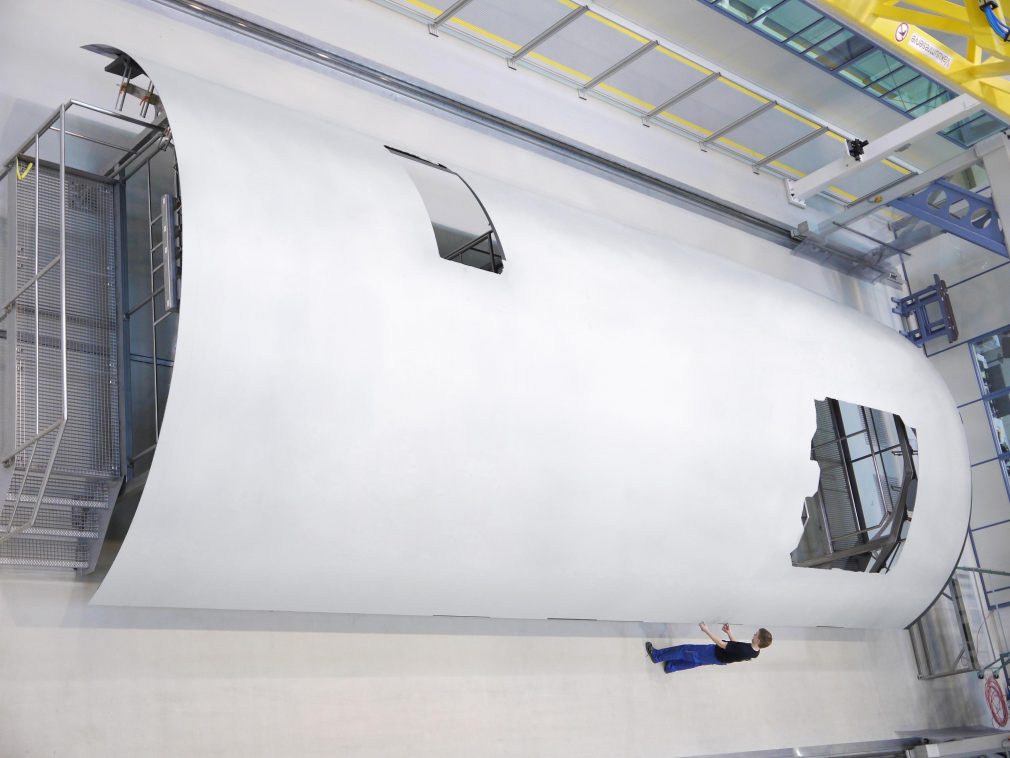

“In aviation, ship and wind turbine industries, however, they are much more experienced in the use of this lightweight material. Complete wings, airplane fuselages and wind turbines are constructed of composite materials.” The picture shows a composite panel for an Airbus aircraft.

Regulation

“The railway sector has to deal with regulations that do not automatically allow the use of composite materials. The legislation is properly regulated for steel structures, which means that it is easier to get certification for trains with a steel car body. The goal of the RESFRESCO project is to identify current legislation and to find out what is missing.”

The research will initially focus on subjects such as strength, crash and fire resistance, noise and vibration, electromagnetic compatibility (EMC) and maintainability. The researchers will take to account earlier studies from other industries such as aviation, aerospace, automotive and shipping, which already has extensive knowledge of the use of composites. “Through this research we are trying to learn more about, for example, aircraft emissions, in order to proof that composites are useful materials for trains. What are the best practices? How is maintenance done? And how do you deal with damage?”

Maintenance

The use of composite materials will lead to various changes in the railway industry. “The entire maintenance process will change radically. Maintenance buildings will have to be equipped for it. In addition, technicians will have to be trained to work with composites.”

Currently, the prices of composites are higher than of steel constructions, but this is expected to change in the future. “What you see is that the price of these materials is slowly going down, because the automotive industry is also increasingly making use of them,” says Wolf. “There are also more and more factories producing raw materials for composites. We hope that the price will reduce further in a few years’ time. In the research we do not focus on the price, but on if we can actually get proper legislation to make the construction of composite trains possible.”

REFRESCO

REFRESCO is supported by the European Commission under the Seventh Framework Programme. This programme, which will have run for 2.5 years, will reach completion in February 2016. The European Commission made a budget of 4.6 million euro available for this project. 18 European partners are collaborating on the project, including Ricardo Rail in Utrecht with its specialist knowledge of regulations.

The project management is in the hands of UNIFE, the railway industry’s international representative. Upon project completion in February 2016, REFRESCO’s researchers will give their recommendations. That does not mean that the project will be completed, says Wolf. “In a follow-up project, we want to build a demonstration model. This will be a train with a composite car body that will run on a track during a pilot scheme.”

Martijn Wolf is one of the speakers at the Rail Technology Conferences in Paris on 17th, 18th and 19th November. This event will take place in the UIC headquarters and will give rail professionals inside information about the themes of Wheel/Rail Interface, Noise and Vibrations and Railways and Environment.

Please click here to register for this interesting event:

https://www.railtech.com/paris-conference-2016/register/