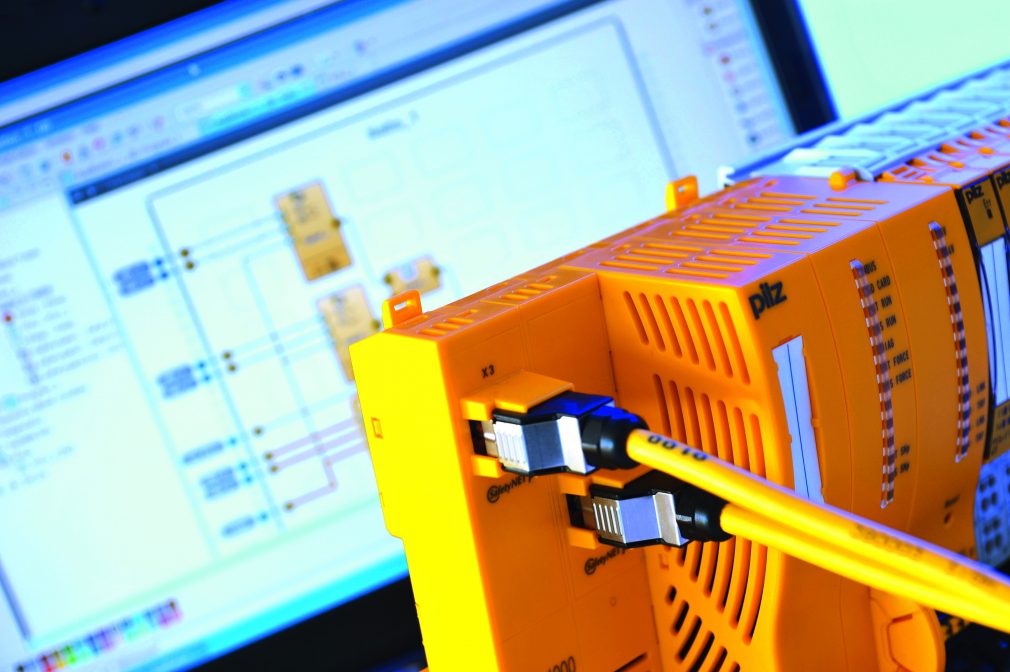

Technological change in the control box

Why the Antwerp metro is more punctual with the Pilz automation system PSS 4000

Want to read more?

You have read all of your free premium articles for this month. Please become a subscriber to keep reading.

Subscribe now!

Take advantage of our exclusive offer to get full access to all premium content.