SNCF sets up consortium to fast-track 3D printing

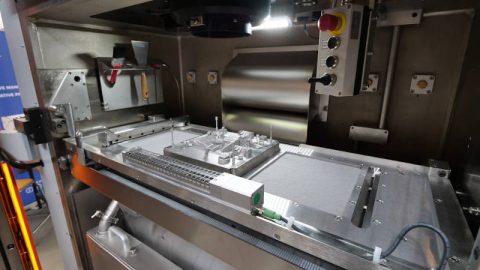

Image: Centrale Nantes,

SCNF set up a new consortium earlier this month to accelerate the development of 3D printing on an industrial scale. Along with partners Centrale Nantes, VLM Robotics and 4D Pioneer, the railway company hopes this process can optimise train maintenance and reduce costs.

Want to read more?

You have read all of your free premium articles for this month. Please become a subscriber to keep reading.

Subscribe now!

Take advantage of our exclusive offer to get full access to all premium content.