voestalpine Signaling readies image-based wayside monitoring equipment

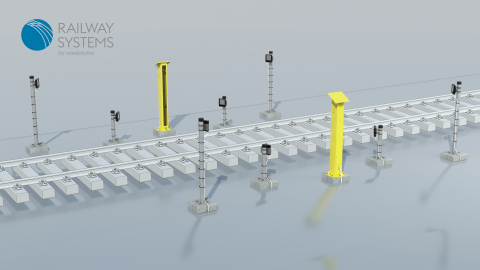

voestalpine Signaling is gearing up for the market launch of its MDS Visual Train Analysis (VTA) system. While the company is the worldwide frontrunner in terms of the number of wayside monitoring systems it includes in its modular diagnostics suite, market analyses and customer enquires point to the necessity of image-based wayside monitoring equipment, voestalpine Signaling Managing Director – CSO Stefan Distlberger tells RailTech. voestalpine Signaling is a subsidiary of the global leading company in the field of railway infrastructure,voestalpine Railway Systems.

Want to read more?

You have read all of your free premium articles for this month. Please become a subscriber to keep reading.

Subscribe now!

Take advantage of our exclusive offer to get full access to all premium content.

Suddenly, now LCC, by far…, are too high – simply “Bottleneck” of Industry – and Reason, for “predictive maintenance”, of “optimal”… (of repairing…).

Low price (“Standards”…) regrettably, has passed – best before date…

At derailments…(apart of those track related, majority) among individual, broken rails, by far, is most frequent. (Currently, high quality steel,

Rail, now is “Fuse”, the informer – of fatigue…) For sustainability, now basics, safe, serious, SWL is requested!…