‘Dutch Betuwe route is ideal for testing ATO on freight trains’

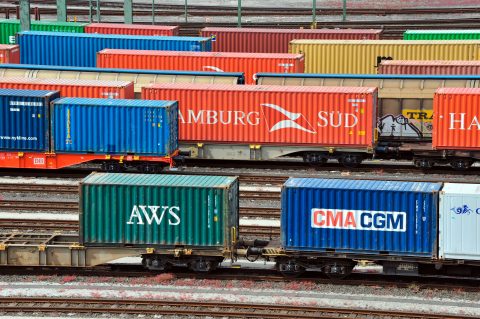

source: Deutsche Bahn DB

DB Cargo and ProRail are starting a new tests with Automatic Train Operation tests on important Dutch freight corridor. “The Betuwe route is a very interesting track which is optimised for freight, with ETCS and no level crossings”, says Baseliyos Jacob, senior engineer at DB Cargo at the ATO Live Event in the Netherlands. 72 percent of freight traffic between Rotterdam and Germany goes via the Betuwe route.

Want to read more?

You have read all of your free premium articles for this month. Please become a subscriber to keep reading.

Subscribe now!

Take advantage of our exclusive offer to get full access to all premium content.